Wheel Tech Car Rims Overview

The term “car rim” refers to the wheels of an automobile. The standard wheels found on most automobiles are basic steel wheels, and many car owners opt to purchase upgraded wheels from the manufacturer or from aftermarket suppliers. Custom car rims are often made of aluminum and magnesium alloys and are available in a wide range of styles and sizes for most automobiles.

Rim Construction

There is a good variety of ways of constructing wheels. Most alloy wheels are made in one, two, or three-piece construction types. One piece is just what it says, a wheel made in a mold as a single piece. Two-piece wheels are made of two separate pieces (center and barrel) that are usually welded or bolted together. Three-piece wheels are made of three separate pieces. They have a center and inside rim half and an outside rim half. They are bolted together using the highest quality fasteners.

The manufacturing method is very important in the overall quality and performance of a wheel. Here are the most common types of manufacturing techniques employed:

Forging:

Considered to be the best manufacturing technique, forging allows for the compression of an aluminum billet (one solid piece of aluminum) into an aluminum wheel using over 13 million pounds of pressure combined with heat. This produces a wheel that is both stronger and lighter than your standard aluminum wheel.

Low-pressure Casting:

This is the most common form of rim manufacturing. Much like a casting, liquid metal is poured into a mold and allowed to harden until the finished wheel is cool enough to be taken out of the casting.

Counter Pressure Casting:

Opposite to low-pressure casting, the liquid metal is not poured; rather, it is sucked into the mold using a vacuum. This reduces impurities making the wheel much stronger than a low-pressure cast rim.

Alloy vs. Steel

The main differences between alloy and steel rims lie in their durability and strength. Most high-performance wheels are made of an alloy and composed of aluminum and other metallic substances. By using alloy wheels, you not only improve the looks of your vehicle but also the performance. The extra strength provides longevity as well as effecting tire wear in a positive manner.

The weight reduction will improve steering response and handling, as well as help, improve acceleration and braking.

New Trends

Chrome wheel rims have always been popular due to their shiny exterior, but other types of alloy rims have appeared in the past 10 years. Custom alloy rims include magnesium rims that have been x-rayed and heat tempered to ensure their good looks and durability. Buyer beware, however, when purchasing a car rim package, make sure that price is not your primary decision-making factor.

Rim Care

It is important to keep your wheels clean at all times. Your brakes will cause the wheels to heat up, and this heat, in turn, can cause any dirt or brake dust to cook into the clear coat. If this happens, there’s not a lot you can do besides having the wheels refinished. Protect your investment and keep your wheels clean!

Below are some simple instructions on how to take care of your wheels:

- Do not use household cleaners or other detergents to clean your wheels. The best wheel cleaning solution is mild soap and water.

- Clean with a soft, un-abrasive cloth. Only on polished wheels can you use aluminum wheel polish. If you use this polish on chrome, painted, or clear-coated wheels, you will only scratch or dull the finish.

- Do not use steam cleaners in automatic car washes.

- Do not use any tire cleaners on your wheels.

- Clean wheels when they are cool. Heat can have an effect on the soap, causing it to dry on the wheel and become difficult to rinse off.

- Clean one wheel at a time. This also prevents the soap from drying onto the wheel.

- After the wheels are clean and dry, apply a coat of soft paste-style wax to them. This will create a moisture barrier and help ensure the finish lasts as long as possible.

Plus Sizing

To enhance the look of your vehicle and improve its performance, you can increase the size of the wheel. “Plus Sizing” is a term that refers to increasing the size of the car rim to the wheel. Plus sizing is chosen by drivers for steering response, handling, and cornering ability. When you add inches to the tire, there is more surface that is in contact with the road. Plus sizing a wheel also enhances the sporty look of a vehicle. Plus sizing can be done by “inching up”. The following are the three methods of “inching up” your tire. “Inching up” means putting a larger sized wheel on a lower profile size tire or putting a wider tire size on your O.E and aftermarket wheel with the same overall tire diameter from the factory.

Plus Zero:

The Plus Zero method uses the same wheel radius as the original equipment but includes a tire with a larger size than the original’s width but smaller than the aspect ratio. For example, the original tire size is 225/75R15. By putting a 245/70R15 tire on this wheel rim, you would not be increasing the tire size, hence “plus zero”.

Zero Plus One:

Plus one increases the size of the tire by one inch. For example if the tire size is 245/75R16 and you put a tire on it that is 245/70R17, you have increased the tire size by one inch. Zero plus one utilizes a one-inch larger diameter wheel in conjunction with a smaller tire. This method always requires a replacement wheel.Zero Plus Two:

Exactly as the name of the method implies, this approach increases the size of the tire by two inches. For example, you would replace the original equipment of 205/75R15 with a tire size of 215/60R17.Customized Rims

For vehicles that are primarily street-driven, the advantages of aftermarket wheels are better performance and gas mileage due to reduced weight and rolling momentum; these advantages can be lost if one chooses to use larger wheels. At some point, the performance advantage of larger wheels and reduced-profile tires meets the performance disadvantage of increased inertia and increased unsparing weight. This point will vary depending on the vehicle, style of wheel, and driving style; however, most vehicles will not see a performance increase when rims are increased more than two sizes from the original-equipment specifications.

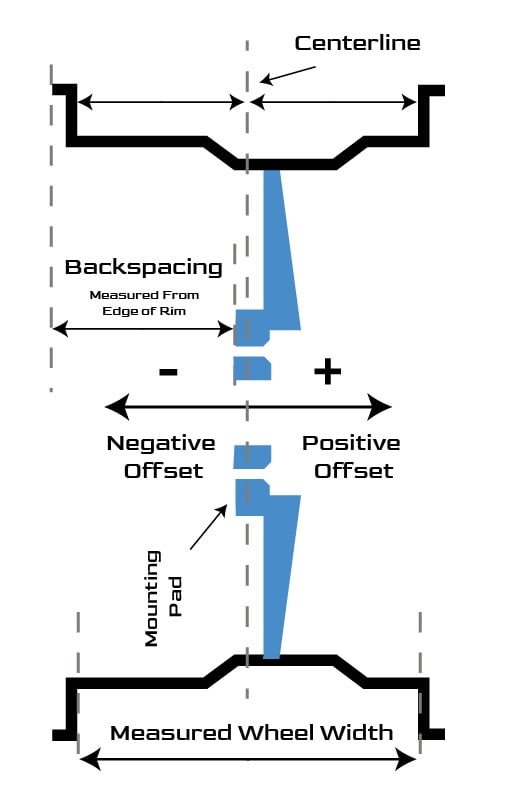

Offset

The offset of a vehicle’s wheel is the distance between the centerline of the wheel and the plane of the hub-mounting surface of the wheel. It can thus be either positive or negative and is typically measured in millimeters. Offset has a significant effect on many elements of a vehicle’s suspension, including suspension geometry, clearance between the tire and suspension elements, the scrub radius of the steering system, and visually, the width of the wheel faces relative to the car’s bodywork.

- Zero Offset: The plane of the hub mounting surface is even with the centerline of the wheel.

- Positive Offset: The plane of the hub mounting surface is shifted from the centerline toward the front or outside of the wheel. Positive offset wheels are generally found on front-wheel drive cars and newer rear-drive cars.

- Negative Offset: The plane of the hub mounting surface is toward the back or brake side of the wheel’s centerline.

Wheels are usually stamped with their offset using the German prefix “ET,” meaning “Einpresstiefe” or, literally, “insertion depth.” An example would be “ET45” for a 45mm offset.

Centerbore

The centerbore of a wheel is the size of the gap in the back of the wheel that centers it over the mounting hub of the car. Some factory wheels have a centerbore that matches exactly with the hub to reduce vibration by keeping the wheel centered. Wheels with the correct centerbore to the car they will be mounted on are known as hubcentric. Hubcentric wheels take the stress off the lug nuts, reducing the job of the lug nuts to center the wheel to the car.

Wheels that are not hubcentric are known as lugcentric, as the job of centering is done by the lug nuts assuming they are properly torqued down. Centerbore on aftermarket wheels must be equal to or greater than that of the hub, otherwise the wheel cannot be mounted on the car. Many aftermarket wheels come with “hubcentric rings” that lock or slide into the back of the wheel to adapt a wheel with a larger centerbore to a smaller hub. These adapters are usually made of plastic but also in aluminum.

Bolt Circle

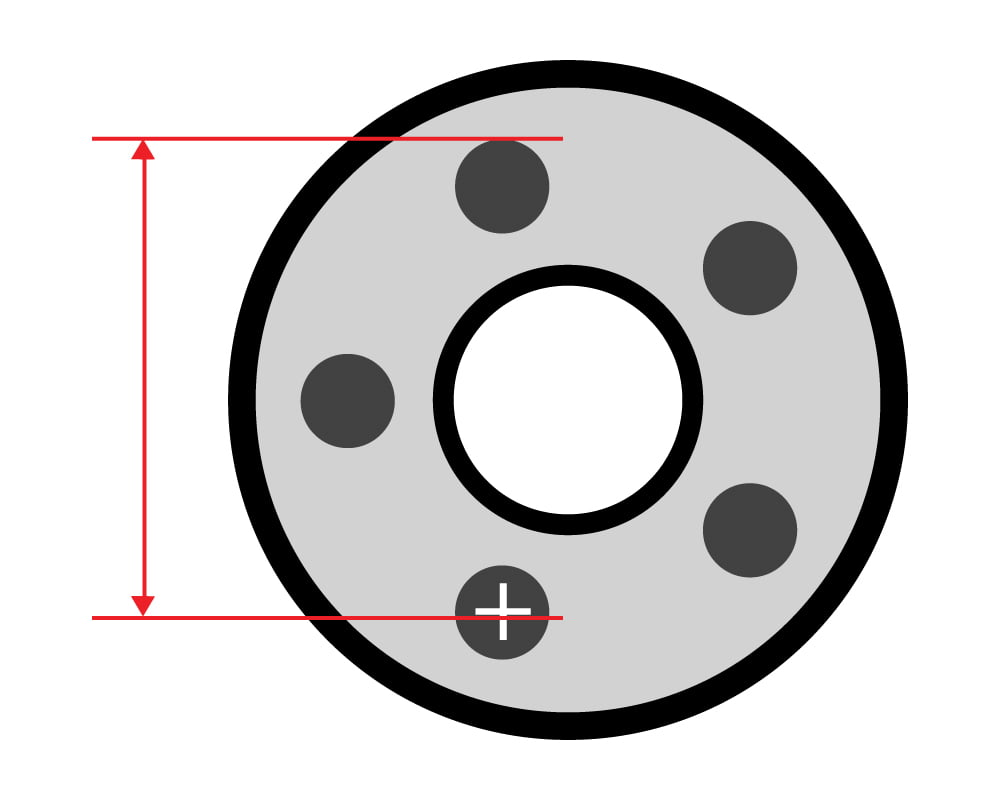

The most common BCD values are 100 mm (≈3.94 inches) and 4.5 inches (114.3 mm).

Bolt Pattern

The bolt pattern is the number of bolts on the wheel hub. As the bolts will be evenly spaced, the number of bolts determines the pattern. For example, most US passenger cars have 5 bolts. Compact models may have only 4 bolts; Pickup trucks and large SUVs can have as many as 6 or 8. Some smaller European cars only have three bolts. For example, the Smart Fortwo.

Wheel Torque

Proper installation requires that the wheel lug torque be set to the recommended specification for your vehicle. These torque specifications can be found in your vehicle’s owner’s manual, shop repair manual, or obtained from your vehicle dealer.

Since the thickness of an alloy wheel can differ from Original Equipment wheels, also verify that the lug nuts or bolts will engage the threads. Refer to the chart below to determine the number of turns or the depth of engagement typical for your stud or bolt size.

When installing new wheels, you should re-torque the wheel lugs after driving the first 50 to 100 miles in case the clamping loads have changed following the initial installation.

This is necessary due to the possibility of metal compression/elongation or thermal stresses affecting the wheels as they are breaking in, as well as to verify the accuracy of the original installation. When rechecking the torque value, wait for the wheels to cool to ambient temperature (never torque a hot wheel). Loosen and retighten to value in a sequence. Simply repeat the same torque procedure listed above.